Walk-In Coolers, Freezers & Combination Models

Walk-in Coolers from Dade, are designed to maintain optimal temperatures for perishable goods in commercial and industrial settings. Walk-in Coolers & Freezer units provide ample storage for various applications, including foodservice operations, convenience stores, and healthcare facilities. Engineered for efficiency and durability, walk-in coolers are customizable to fit specific project requirements and are built to withstand daily use. With advanced insulation technology, they ensure temperature consistency while minimizing energy consumption, making them a sustainable choice for cold storage solutions. Seamless installation and compliance with industry standards further enhance their reliability, allowing businesses to focus on delivering fresh products to their customers year-round. Our UL and NSF approved walk-in models are supplied with 1-, 10- and 50-year warranties and manufactured in Miami, Florida.

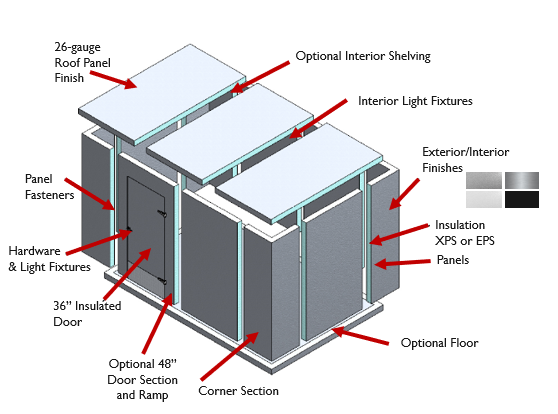

Walk-in Cooler Standard Features

Walk-in sizes range from standard 8' x 8' ft units to custom warehouses.

Available with or without a floor. Freezers must have an insulated floor.

Interior and exterior wall and roof finish is 26-gauge acrylic coated stucco galvanized.

Insulation is 4” thick, rigid extruded polystyrene (XPS) foam closed cell. R-25 for coolers and R-32 for freezers.

Solid entry door measures 36" w x 78" h, windows and accessories available.

High quality door fixtures - chrome plated latches and hinges, proprietary Dade design.

Airtight joints ensure optimal temperature control.

Modular panel construction is easy to assemble, clean, & maintain as well as install.

Additional options available such as windows, kick plates and storage shelves.

Marketing Literature - Download PDF Files

Freezer & Cooler Components

Vapor Proof, LED Light Fixtures with glass globe provided

Optional 4” LED or Fluorescent Extreme Temperature Lights available.

Chrome Plated Latches

Chrome Plated Hinges with Safety Release

Door Closer

Digital LED Thermometer

Heated Pressure-Relief Vent

Extruded Polystyrene Foam

Optional interior shelving

Insulated reinforced floor for freezer is standard, optional for a walk-in cooler

Choose exterior and interior wall finishes

Panel Wall Fastners

Optional insulated door sizes, standard is 36”

Optional door windows and kick plate

Benefits of Insulation - XPS & EPS

Expanded Polystyrene, EPS is produced by expanding polystyrene beads with steam.

Extruded Polystyrene, XPS is made by extruding molten polystyrene and then expanding it using blowing agents.

Benefits of EPS and XPS Insulation Compared to PU (Polyurethane)

Moisture Resistant: XPS/EPS typically has a closed-cell structure, making it more resistant to moisture absorption compared to open-cell PU foam. This property is crucial for insulation materials, especially in environments where moisture ingress can compromise the insulation's effectiveness over time.

R-Value Retention: XPS/EPS tends to maintain its thermal resistance (R-value) over time, whereas PU foam may experience a decrease in R-value due to aging and moisture absorption. XPS/EPS can provide consistent insulation performance throughout its lifespan.

Strength and Durability: XPS/EPS is known for its high compressive strength, making it suitable for applications where the insulation may experience heavy mechanical loads or pressure, it’s more resistant to deformation and can maintain its structural integrity better than PU foam.

Fire Resistance: XPS/EPS has a higher fire resistance compared to PU foam. This property can be critical in buildings where fire safety regulations require insulation materials with specific fire ratings to enhance overall safety measures.

Environmental Impact: XPS/EPS can be manufactured with a lower environmental impact compared to PU foam, especially if recycled content or eco-friendly production methods are used. This aspect is increasingly important in sustainable construction practices and green building certifications.

Wall Finish Options

26 Gauge Acrylume® Stucco Embossed Finish

24 Gauge Smooth Stainless Steel

26 Gauge Stucco Embossed White Pre-Painted Galvanized Steel

White, Stainless Steel (Grey) and Black

Optional Accessories

Vinyl Curtain Strip

Diamond Kick Plate

Exterior & Interior Ramp

Insulated Viewing Windows

Interior Shelving Units

Customize, Outdoor, Repairs, Floors & more!

CUSTOMIZE

Dade can tailor your walk-in cold storage solutions. You’re not limited to standard options; we can design to meet your specific space, safety needs, and compliance regulations.

Customize options include but not limited to square footage, electronics, doors, finishes, hardware, windows, shelving, floors, ramps, lighting, outdoor models, and walk-in cooler freezer combo

OUTDOOR

Outdoor walk-in coolers, freezers, and combination units are designed for both warm and cold settings. They feature a rainproof roof membrane on the inside, complete with flashing. We use anchoring hardware and a door rain cap to maintain a controlled temperature.

WALK-IN COOLER REPAIR or UPGRADE

Dade can repair, upgrade, or retrofit your walk-in, doors or frame. Often, just repairing or retrofitting can extend the life of your walk-in and improve efficiency. Replacement parts can be ordered for most walk-in models and should be installed by qualified professionals.

FREEZER FLOORS

Walk-in Freezer floors are essential. Insulating under concrete and wood floors can help prevent condensation from high humidity which can cause rot and bacteria growth. Always check local codes.

Walk-in Freezer floor is constructed of 22 ga Smooth Mill Floor Plate, 4” Extruded Polystyrene Foam (EISA 2007 Approved), NSF gasket with Cam-Locks hardware and built-in ramp.

QuickShip Program

We are pleased to offer QuickShip Program on our popular standard walk-in units, which come in sizes of 8’ x 8’, 8’ x 10’, and 10’ x 10’ ft. In addition to these units, we also provide any necessary door replacements or parts that you might need to ensure that your refrigeration expectations are fully met. Should you require further assistance, wish to place an order, or need a walk-in cooler repair or parts, please do not hesitate to contact us for support.

Contact customer service at 800-321-2112

Email Dade at quotes@dadecoolers.com

About Dade Engineering Products, Click to download Trifold Brochure